Have you ever wondered what silent workhorse empowers the precise movements in countless modern machines, from advanced factory robots to sophisticated medical equipment? The answer often lies with the LM guide rail, a critical linear motion component. This comprehensive article delves into what LM guide rails are, how they function, and why their advanced engineering is not just important but absolutely essential in todays rapidly evolving technological landscape. We will explore their widespread applications across industries, uncover the compelling benefits they offer in terms of precision and efficiency, and look into the cutting-edge innovations that are driving their continued relevance. This informational deep dive is designed for anyone curious about the mechanics behind modern automation, providing a clear understanding of why LM guide rails are a trending topic for their pivotal role in shaping the future of manufacturing, healthcare, and beyond, ensuring smooth and reliable operation that underpins our technological progress. We aim to clarify the why and how of these indispensable motion control solutions, offering valuable insights into their impact.

Why do so many modern machines move with such incredible precision and quiet grace? What exactly enables the intricate dance of automation we witness daily, from the robot arm perfectly placing components to the sophisticated medical scanner delivering crystal-clear images? We often take for granted the underlying mechanics, but the answer frequently involves an unsung hero: the LM guide rail. This vital component, with LM standing for Linear Motion, is fundamentally what allows machinery to move along a straight path with minimal friction and maximum accuracy. But how do these unassuming rails, found everywhere from advanced manufacturing plants to everyday packaging lines, orchestrate such flawless operation, and what makes them an indispensable part of todays high-tech landscape? When did they become so critical to modern industry, and where are they making the biggest impact on our world, empowering the innovations we rely on? This journey into LM guide rail technology will clarify their crucial role and undeniable importance, helping you understand the silent power behind smooth, controlled movement.

The Essence of LM Guide Rail: How They Work

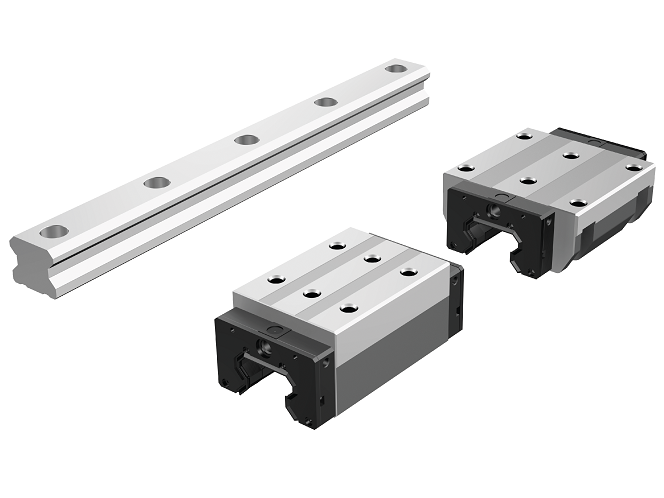

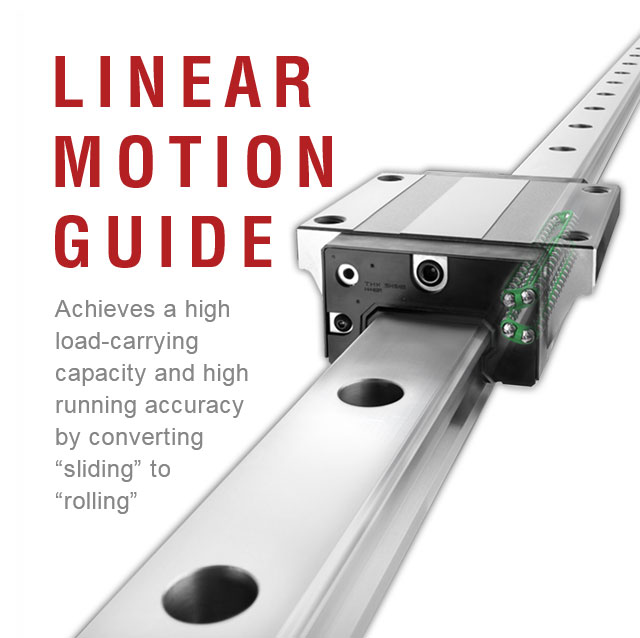

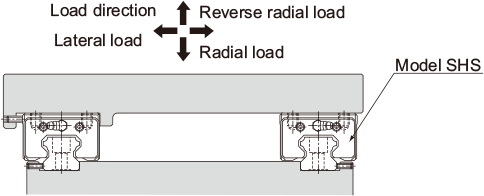

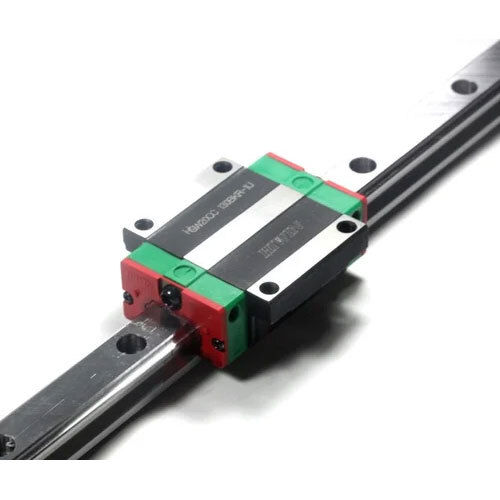

What exactly defines an LM guide rail system, and how does it manage to achieve such remarkable linear movement, making it a cornerstone of modern engineering? At its core, an LM guide rail is a mechanical component specifically engineered to provide precise linear motion along a predefined path. It typically consists of a meticulously ground, hardened steel rail, crafted for exceptional straightness, and a bearing block—often referred to as a carriage or runner—which glides smoothly along this rail. Inside this carriage, rows of recirculating ball bearings or rollers enable the incredibly smooth, low-friction movement. Why is this specific design so effective and universally adopted? Because these rolling elements transform what would otherwise be high-resistance sliding friction into significantly lower rolling friction, drastically reducing resistance and wear, making it much easier for a machine to move heavy loads with minimal effort. How do manufacturers ensure this extraordinary level of precision and durability, and who benefits most from incorporating such advanced engineering into their critical systems? Continuous innovation in materials science and advanced manufacturing processes ensures these systems offer unparalleled stiffness and load-bearing capacity, cementing their status as the preferred choice for applications where accuracy, reliability, and longevity are non-negotiable requirements, continually proving their worth in demanding environments.

Why LM Guide Rails are Essential and Where They Thrive

Why are LM guide rails garnering so much attention and becoming a truly trending topic across various industries in the United States and globally? The burgeoning demand for automation, robotics, and advanced manufacturing processes is largely responsible for this surge in interest. As companies relentlessly strive for higher productivity, greater precision, and significantly reduced operational costs, the efficiency and steadfast reliability offered by LM guide rails become absolutely paramount. Where do we witness their profound influence and impact most prominently? From the high-speed assembly lines producing our cutting-edge smartphones and innovative electric vehicles to the intricate machinery performing delicate surgeries in hospitals, these linear motion components form the very backbone of countless operations. Consider the massive gantry systems in automated warehouses, moving pallets with impressive ease, or the hyper-precise positioning systems in 3D printers, creating complex prototypes with astonishing accuracy; what makes all these diverse and critical applications possible is the consistent, repeatable, and exact motion delivered by robust LM guide rail systems. When we consider the relentless, accelerating drive towards Industry 4.0 and smart factories, it becomes abundantly clear why understanding and implementing high-quality LM guide rail solutions is more critical now than ever before for businesses seeking a powerful and enduring competitive edge in a global market.

Unpacking the Benefits: Who Gains from LM Guide Rail Technology

What are the undeniable, tangible benefits that transform LM guide rails into an essential, indispensable investment for so many forward-thinking businesses, and who truly stands to gain the most from their sophisticated design and impeccable performance? The advantages are both numerous and compelling, starting with their unparalleled precision. These advanced systems ensure that movement is incredibly accurate and consistently repeatable, a factor that is absolutely crucial for applications where even a tiny deviation can lead to significant errors, such as in highly sensitive CNC machining, critical optical inspection equipment, or delicate laboratory automation. Furthermore, their remarkably low friction properties translate directly into substantial energy efficiency, thereby reducing power consumption and significantly cutting operational costs over extended periods. But how exactly do they achieve such extraordinary durability, and why is this unwavering resilience so critically important for demanding industrial settings? Built from robust, high-grade materials and meticulously engineered to effortlessly withstand heavy loads and continuous, punishing operation cycles, LM guide rails offer an exceptionally extended service life, which translates directly into minimized downtime and substantially reduced maintenance requirements. Who ultimately gains the most from these engineering marvels? Manufacturers striving for consistent, superior product quality, innovative researchers building precise experimental setups, and even everyday consumers who benefit from the higher quality, more reliable, and often more affordable products produced by these incredibly efficient machines. It stands as a profound testament to engineering excellence that such a fundamental component can wield such a profound and far-reaching impact across such a vast and diverse spectrum of human endeavor and innovation.

The Future of Linear Motion: Advancements in LM Guide Rail Systems

How are LM guide rail technologies continuing to evolve, and what does the future hold for these essential components of sophisticated motion control systems? The innovation cycle for LM guide rails is relentless and continuous, primarily driven by ever-increasing demands for even greater speed, enhanced precision, and deeper integration of intelligence. Manufacturers are constantly engaged in intensive research into novel materials for even greater durability and lighter weight, relentlessly pushing the boundaries of what is possible in terms of load capacity, stiffness, and operational longevity. Why is the integration of smart features, such as advanced sensors for real-time monitoring of critical parameters like temperature, vibration, and lubrication levels, becoming increasingly important and highly sought after? This sophisticated integration enables predictive maintenance strategies, allowing potential issues to be identified and addressed proactively before they can escalate into costly breakdowns, thereby maximizing valuable uptime and optimizing overall operational efficiency. Where might we witness the next truly significant leap in LM guide rail technology? Perhaps in groundbreaking self-lubricating systems that further reduce maintenance requirements, or in guide rails specifically designed for extreme, challenging environments, such as the vacuum of outer space or the crushing pressures of deep-sea exploration, where conventional lubricants and materials might utterly fail. The ongoing quest to refine and perfect these linear motion systems ensures that they will consistently remain at the absolute forefront of technological advancement, powering the machines that shape our future, continually asking: what new frontiers can we conquer with even smoother, more precise movement?

| Feature | Description | Why it matters |

|---|---|---|

| Precision | Ability to maintain exact linear path with minimal deviation. | Critical for applications like CNC machining, medical devices, and robotics, ensuring accuracy. |

| Load Capacity | Maximum weight or force the guide rail system can safely support. | Ensures stability and durability for heavy-duty industrial tasks and demanding applications. |

| Stiffness | Resistance to deformation or bending under applied load, maintaining accuracy. | Prevents unwanted deflection, which is crucial for consistent performance and product quality. |

| Low Friction | Minimal resistance during movement, achieved by rolling elements (balls/rollers). | Increases energy efficiency, reduces wear on components, and significantly extends the systems lifespan. |

| Corrosion Resistance | Ability to withstand rust, chemical attack, and degradation in harsh environments. | Extends operational life and reliability in humid, chemical-laden, or outdoor settings. |

Summary Question and Answer

What are LM guide rails? They are precision mechanical components that provide highly accurate, low-friction linear motion for machinery across a vast array of industries. Why are they so crucial today? They enable the seamless, efficient operation of automation, robotics, and advanced manufacturing by providing consistent, high-precision movement, boosting productivity, reliability, and innovation in countless applications worldwide. How do they achieve this? Through a clever design involving hardened rails and recirculating bearing blocks that convert sliding friction into efficient rolling friction, making them essential for moving the world forward. Keywords: LM guide rail, linear motion, guide rail, precision machinery, industrial automation, robotics, CNC machines, material handling, linear bearings, motion control, low friction, high precision, automation solutions, industrial components, mechanical engineering, factory automation.

Precision Linear Motion, Industrial Automation Backbone, Enhanced Durability, Energy-Efficient Operation, Wide Industry Adoption, Predictive Maintenance Potential

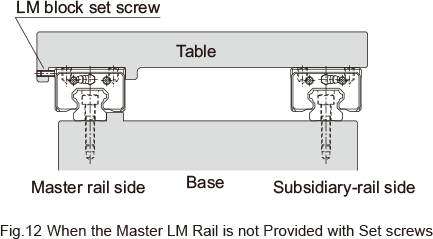

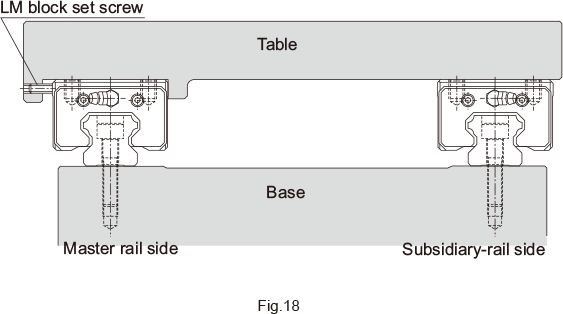

Mounting Procedure Mounting Procedure And Maintenance LM Guide Product Lm Guide En Maintenance Img 12 Designing The Guide System Point Of Design LM Guide Product Information Lm Guide En Design Img 01 Designing The Guide System Point Of Design LM Guide Product Information Lm Guide En Design Img 03

Lm Guide Rail With Slider Block Hzh30 Linear Motion Guide Way Bearing Lm Guide Rail With Slider Block Hzh30 Linear Motion Guide Way Bearing For CNCLm Guide Rail With Slider Block Hzh30 Linear Motion Guide Way Bearing Lm Guide Rail With Slider Block Hzh30 Linear Motion Guide Way Bearing For CNCLM Guide Product Information THK Official Web Site Lm Guide En Img F19 Hard Steel Silver Lm Guide Rail Size 15mm To 45mm At 499 Piece In Lm Guide Rail 500x500

Linear Guides Linear Motion Guides Design And Selection THK Linearguide Lp Eng 2 Lm Block And Rail Linear Guideways At 1000 00 INR In Pune Saiprasad LM Block Rail Linear Guideways LM Guide GK Series LM Guide Product Information THK Official Web Site Lm Guide Gk Series Linear Guides Linear Motion Guides Design And Selection THK Main Linearguide Lp Test

Lm Guide Rail With Slider Block Hzh20 Linear Motion Guide Way Bearing Lm Guide Rail With Slider Block Hzh20 Linear Motion Guide Way Bearing For CNC Machine Jual THK LM Rail HSR25 Untuk Linear Guide Block HSR25C HSR25R 72dac0ec E163 4d1c 8936 THK Debuts Fast LM Guide With Speeds To 15 M Sec THK PR Web Original THK Lm Linear Motion Guide Rail SSR15xw SSR 15xw For CNC Original THK Lm Linear Motion Guide Rail SSR15xw SSR 15xw For CNC Machine

Stainless Steel Linear Motion Guide Rails And Blocks Standard Linear Guides From THK MISUMI MEXICO 001 Linear Guide Rail Lm Guide Rail From Coimbatore Product Jpeg 250x250 Lm Guide Rail With Slide Block Hzh15 Linear Motion Guide Way Bearing Lm Guide Rail With Slide Block Hzh15 Linear Motion Guide Way Bearing For CNC Machine

Guide Rail Home Guide Rails Latest Price Suppliers Lm Guide Lmguide Rails 500x500 Chh25ca Linear Motion Guide Rail Guide Rail And Lm Guide LinearGuide 3 Mp4.webpLM Guide Rail The Core Component Of High Precision Drive Systems CSK LM Guide Rail Linear Guideway Linear Guides Latest Price Suppliers Lm Guide Linear Motion Guide 1000x1000

Mounting Procedure Mounting Procedure And Maintenance LM Guide Product Lm Guide En Maintenance Img 16 Lm Guide Rail With Slider Block HGH20 Linear Motion Guideway Linear Lm Guide Rail With Slider Block HGH20 Linear Motion Guideway Linear Bearing For CNCWhat Is LM Guideways LM Block LM Rail YouTube Hqdefault Factory Direct Custom Heavy Duty Linear Guide Rail With 35mm Slider Linear Guides

Products MECH LINEAR SYSTEMS P1 I1 W957 Low Precision Arc Curved Rail Guide Linear Motion Guide Lm Guide Low Precision Arc Curved Rail Guide Linear Motion Guide Lm Guide Standard Linear Guides Linear Guides MISUMI 001 Stainless Steel LM Guide Rail At 3500 Piece Guide Rail In Chennai Stainless Steel Lm Guide Rail

Linear Guide Explained Linear Motion Systems SLS Bearings Back Wall FINAL Linear Slide Max.webpProduct Information THK Official Web Site Singapore Lm Guide HIWIN LM Guide Rail And Block At 5000 Piece Linear Guideway In Guide Rail 1000x1000 Mounting Procedure Mounting Procedure And Maintenance LM Guide Product Lm Guide En Maintenance Img 18