Are you wondering how to make your concrete projects stronger and last longer? This essential concrete reinforcement guide unlocks the secrets to preventing cracks, boosting durability, and ensuring the safety of your structures. Whether you are pouring a new patio, strengthening a foundation, or repairing an existing slab, understanding proper reinforcement is paramount. We delve into the crucial why behind reinforcement, exploring the forces that challenge concrete and how strategic materials like rebar and mesh provide the necessary backbone. Discover the various types of reinforcement available, from steel rebar to wire mesh and even fiber additives, learning when and where each is most effective. This guide also illuminates best practices for installation, ensuring that your reinforcement performs exactly as intended for decades to come. Get ready to empower your next DIY project or professional endeavor with the knowledge to build resilient, long-lasting concrete surfaces that stand the test of time, saving you headaches and costly repairs down the road. This comprehensive resource is designed to be your go-to reference for all things concrete strengthening, making complex concepts easy to grasp and apply.

Have you ever wondered why some concrete surfaces crack while others seem to last forever, and what who is responsible for preventing this common issue? The what of concrete reinforcement is the secret sauce to building durable, resilient structures, essential when undertaking any concrete project, from a simple backyard patio to a robust foundation. This comprehensive concrete reinforcement guide will walk you through the how to achieve superior strength, whether you are pouring a new slab or fortifying an existing one. Well explore where reinforcement is most critical and why it’s not just an option but a necessity for longevity and safety. By understanding the principles and practical applications of concrete reinforcement, you, the homeowner or contractor, can confidently tackle projects that stand the test of time, preventing costly failures and ensuring peace of mind. Let’s dive into empowering your concrete endeavors with proven strategies that truly make a difference, transforming ordinary concrete into an extraordinary, long-lasting investment.

Understanding the Why of Concrete Reinforcement: Your Ultimate Concrete Reinforcement Guide

Many people ask, Why bother with reinforcement when concrete seems so strong on its own? The truth is, while concrete boasts impressive compressive strength—meaning it resists being crushed—it struggles significantly with tensile forces, which are pulling or stretching actions. When you pour a slab, it naturally wants to shrink a bit as it dries, and temperature changes cause it to expand and contract. These movements, coupled with external loads like heavy vehicles or furniture, create tension within the concrete, leading to unsightly and structurally compromising cracks. This is where reinforcement steps in, acting as an internal skeleton. Who benefits from this? Everyone who uses the concrete surface, from homeowners enjoying a stable patio to businesses relying on durable warehouse floors. The what reinforcement does is absorb these tensile stresses, effectively holding the concrete together and distributing the forces more evenly across the entire slab. It’s when these stresses occur that reinforcement truly shines, preventing small hairline fractures from becoming major structural failures. Where do you most often see this need? In driveways, sidewalks, foundations, and any structure exposed to varying loads and environmental conditions. Understanding why we reinforce concrete isnt just about avoiding cracks; its about building with confidence, creating structures that offer lasting value and safety for years to come. This proactive approach ensures your investment pays off, providing robust performance and a smooth surface without the headache of early deterioration.

Decoding the Forces: A Concrete Reinforcement Guide to Stress Management

What exactly are these forces that attack your concrete, and how can you effectively manage them? Concrete faces a constant battle against several invisible adversaries, primarily settlement, drying shrinkage, and thermal expansion/contraction. Settlement occurs when the ground beneath your slab shifts or compacts unevenly, creating voids and unsupported sections. Who should be concerned? Anyone building on fill dirt or areas with variable soil conditions. Drying shrinkage is a natural process where concrete loses moisture as it cures, causing it to reduce in volume. This what creates internal pulling forces. Thermal movement, conversely, is the expansion when temperatures rise and contraction when they fall, literally stretching and squeezing the concrete. Where are these most pronounced? In outdoor slabs like driveways and patios, which experience significant temperature swings. Why does reinforcement matter here? Because it distributes these stresses over a wider area, preventing them from concentrating in one spot and forming a crack. Think of it as a team effort: the concrete handles the pushing, and the reinforcement handles the pulling. Understanding these fundamental forces empowers you to choose the right concrete reinforcement guide strategies and materials, transforming a vulnerable slab into a resilient one capable of shrugging off environmental and load-related challenges with ease. This knowledge allows you to build smarter, not just harder.

Choosing the Right Materials for Concrete Reinforcement: A Practical Concrete Reinforcement Guide

With so many options available, how do you pick the best reinforcement materials for your specific project, and who makes these choices? Selecting the appropriate reinforcement is critical for the success and longevity of any concrete structure. The what of your project—whether its a thin topping slab, a heavy-duty driveway, or a foundation for your home—will largely dictate your material choice. When considering materials, think about the expected loads, environmental conditions, and the desired lifespan of the concrete. Steel rebar, or reinforcing bar, is perhaps the most widely recognized form of reinforcement. It offers incredible tensile strength and comes in various diameters, providing serious structural support for heavy loads and significant spanning requirements. Where is rebar most often used? In foundations, walls, columns, and thick slabs that demand high structural integrity. Then theres wire mesh, also known as welded wire fabric (WWF), which consists of a grid of steel wires. Why is mesh popular? Its excellent for controlling shrinkage cracks in thinner slabs like sidewalks, patios, and garage floors, offering uniform distribution of reinforcement. Another option, fibers—like synthetic or steel fibers—can be mixed directly into the concrete batch. What do fibers do? They provide a three-dimensional reinforcement matrix, improving impact resistance, reducing plastic shrinkage cracks, and enhancing overall toughness, especially when used in conjunction with other reinforcement types. Understanding the strengths and ideal applications of each material is key; it empowers you to make informed decisions that ensure your concrete reinforcement guide project performs exactly as intended.

| Reinforcement Type | What It Is | Best For | Key Benefit |

|---|---|---|---|

| Steel Rebar | Deformed steel bars (various diameters) | Foundations, structural slabs, walls, heavy load areas | High tensile strength, structural support |

| Welded Wire Mesh (WWF) | Grid of steel wires (various gauges and spacing) | Driveways, patios, sidewalks, light-duty slabs | Shrinkage crack control, uniform reinforcement |

| Synthetic Fibers | Polypropylene, nylon, or aramid fibers | Slabs, decorative concrete, areas needing impact resistance | Reduced plastic shrinkage cracks, increased toughness |

| Steel Fibers | Small, discontinuous steel filaments | Industrial floors, pavements, areas with high abrasion | Enhanced flexural strength, fatigue resistance |

Mastering Installation Techniques for Concrete Reinforcement: A Step-by-Step Concrete Reinforcement Guide

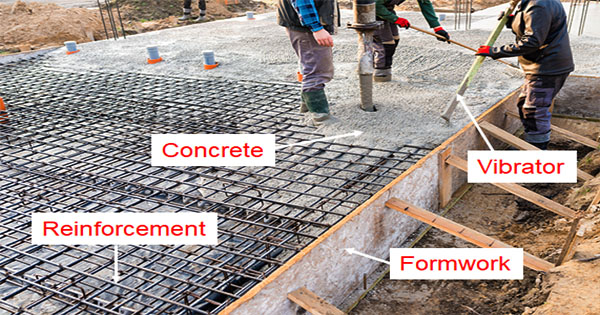

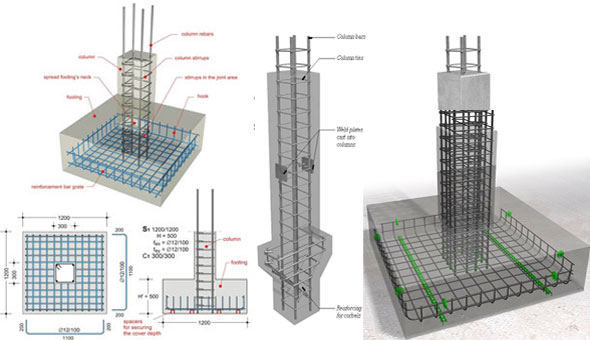

Now that you know what materials to choose, how do you install them correctly to ensure maximum effectiveness, and who typically handles this process? Proper installation is just as vital as selecting the right materials for any concrete reinforcement guide project. Incorrect placement can render even the best rebar or mesh virtually useless. The general rule of thumb is to place reinforcement in the upper third of the concrete slab for crack control, as this is where tensile stresses are highest due to drying shrinkage and surface loads. For structural applications, rebar might be placed in the lower third or even both top and bottom, depending on design. When placing rebar, ensure its adequately supported and tied together with wire at intersections to prevent shifting during the concrete pour. This creates a cohesive cage that acts as a single unit. For wire mesh, lift it into the middle to upper third of the slab as the concrete is being placed. Why is this crucial? Because if the mesh lies directly on the ground, it cannot effectively resist the tensile forces occurring higher in the slab. Use chairs or bricks to support both rebar and mesh, lifting them to their correct height. Who can do this? While professionals are experts, competent DIYers can master these techniques with careful planning and execution. Overlapping sections correctly, maintaining proper clearances from edges, and securing everything firmly before the pour are essential steps. Remember, the goal is to fully embed the reinforcement within the concrete, allowing it to work in concert with the material to create a robust, long-lasting structure.

Ensuring Proper Placement: A Concrete Reinforcement Guide to Depth and Coverage

What is the ideal depth for your reinforcement, and why does it matter so much? The precise positioning of reinforcement within the concrete is paramount, influencing its ability to perform its job effectively. The general principle, known as concrete cover, refers to the depth of concrete surrounding the reinforcement. Too little cover, and your steel can corrode prematurely due to exposure to moisture and chemicals, leading to rust expansion that can spall and crack the concrete around it. Too much cover, and the reinforcement may not be close enough to the surface to effectively resist the tensile forces that often originate there, rendering it less efficient for crack control. When pouring slabs, a common guideline for rebar is to aim for about 2-3 inches of cover from the top and bottom surfaces in typical structural applications, while wire mesh for crack control often sits in the upper half of the slab, typically 1.5 to 2 inches from the top. Who determines these exact depths? Often, engineers specify these based on structural design and environmental conditions. How do you achieve this? By using plastic or metal rebar chairs, often called dobies, which hold the reinforcement at a consistent height above the subgrade or formwork. These small but mighty supports are indispensable for ensuring your concrete reinforcement guide efforts translate into real-world strength and longevity. Dont skip this critical step, as it directly impacts the performance and lifespan of your entire concrete investment. Proper cover is your best defense against future headaches and costly repairs.

Common Pitfalls and Solutions in Concrete Reinforcement: Your Essential Concrete Reinforcement Guide

Even with the best intentions, what common mistakes can people make during concrete reinforcement, and how can you avoid them? While the concept of reinforcement is straightforward, its execution often presents challenges that can undermine the entire project. One frequent pitfall is improper placement – either leaving reinforcement directly on the ground, making it useless for upper-surface crack control, or placing it too close to the surface, leading to corrosion and spalling. Who commonly makes these errors? Often, inexperienced DIYers or those rushing through a job. The solution, as we discussed, involves using proper supports like chairs or dobies to lift the reinforcement to its intended depth. Another common issue is insufficient overlap when joining sections of rebar or mesh. If these overlaps arent long enough or properly tied, the reinforcement essentially acts as separate pieces rather than a continuous, stress-distributing network. Why is this a problem? Because tensile forces will find the weakest link, leading to cracks at these poorly connected points. Always consult guidelines for minimum overlap lengths, which are often specified by local building codes or engineering designs, and securely tie connections. Where do people often overlook this? In large pours where multiple sections are needed. Lastly, failing to protect rebar from rust before or during installation can significantly compromise its long-term effectiveness. What can you do? Use epoxy-coated rebar in corrosive environments or ensure rebar is clean and free of excessive rust before embedding. Adhering to these simple yet critical practices from this concrete reinforcement guide can save you immense trouble and expense down the road, ensuring your concrete stands strong for generations.

Q: Why is concrete reinforcement important? A: It significantly increases concretes tensile strength, preventing cracks and enhancing structural durability by absorbing pulling forces. Q: What materials are commonly used for reinforcement? A: Steel rebar, welded wire mesh (WWF), and various types of fibers (synthetic or steel) are popular choices, each suited for different applications.

Keywords: Concrete reinforcement guide, rebar guide, wire mesh concrete, fiber concrete, crack prevention concrete, concrete slab reinforcement, foundation reinforcement, structural concrete tips, concrete durability, DIY concrete strengthening

Preventing concrete cracks, increasing structural integrity, choosing the correct reinforcement materials, proper installation techniques, common reinforcement challenges and solutions, understanding rebar and mesh.

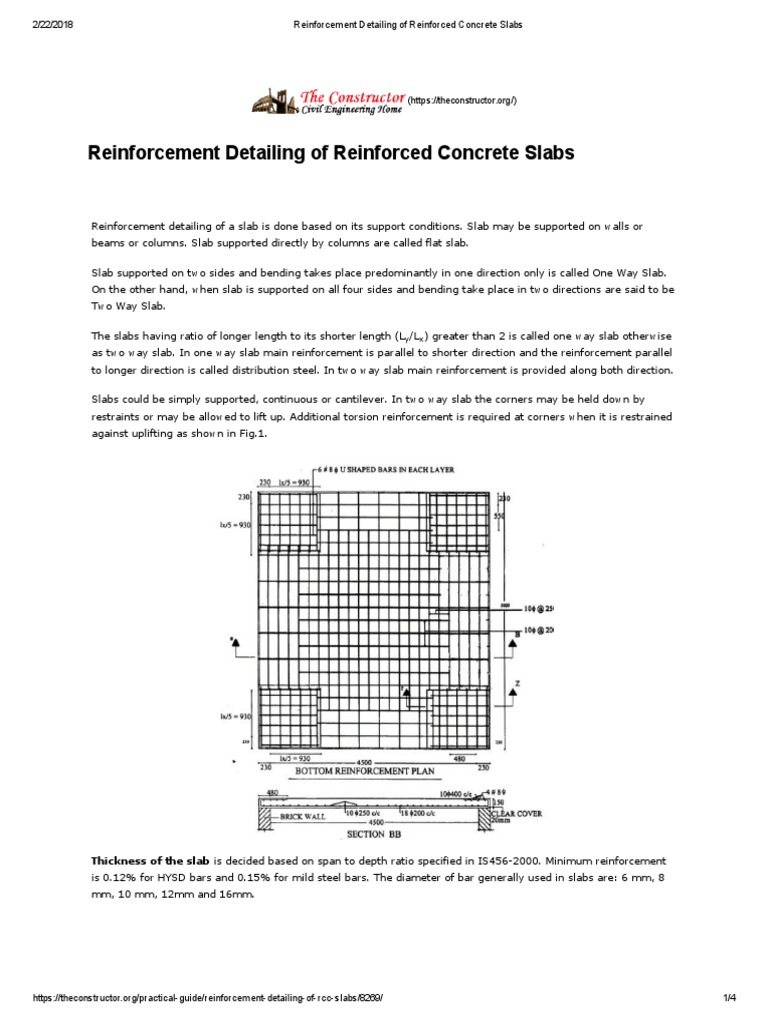

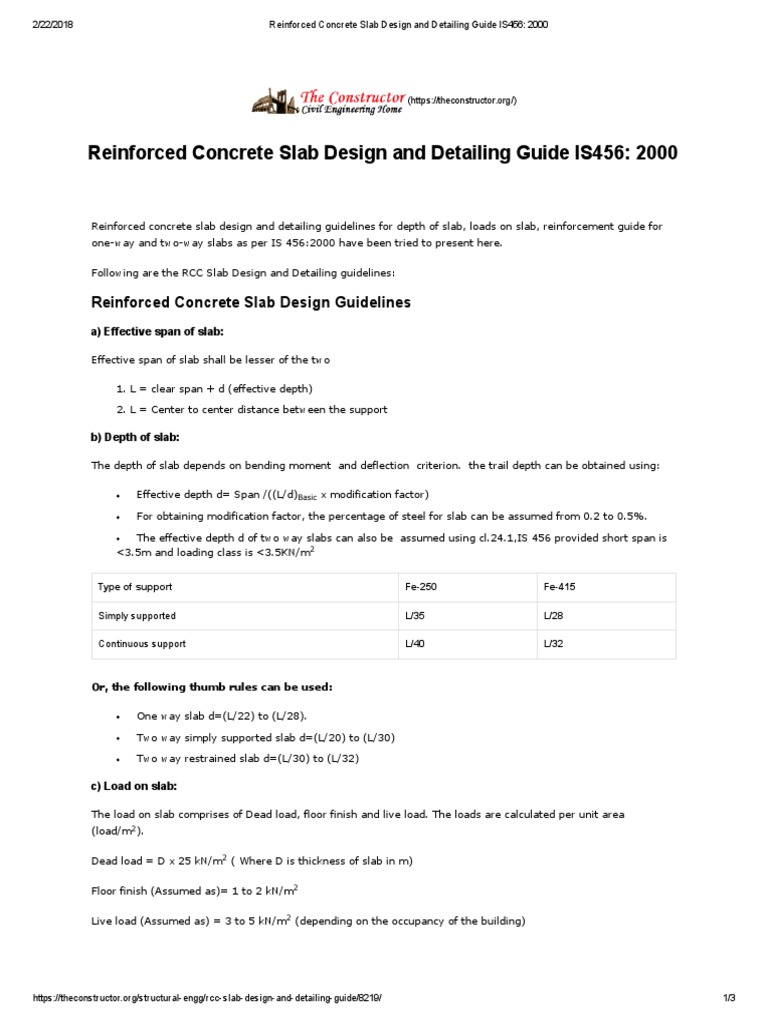

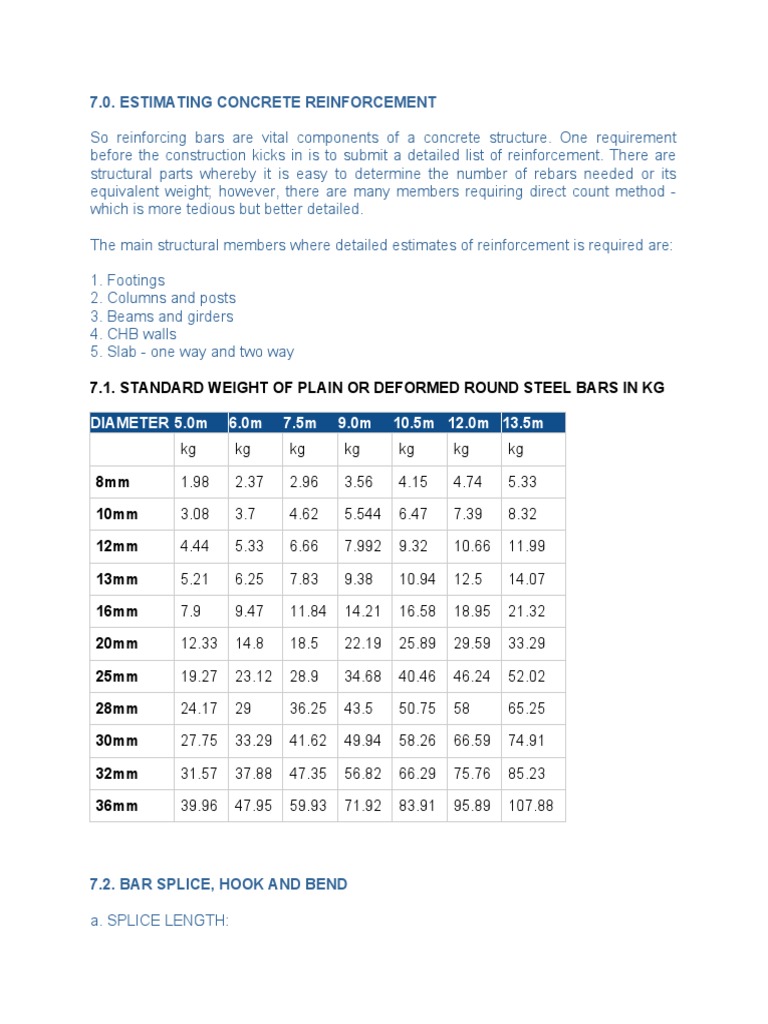

American Concrete Institute Publishes Design Handbook And Recommended Press Release Img1 Concrete A Guide Barrow Image 19 Reinforced Concrete Slab Design And Detailing Guide IS456 2000 PDF 1

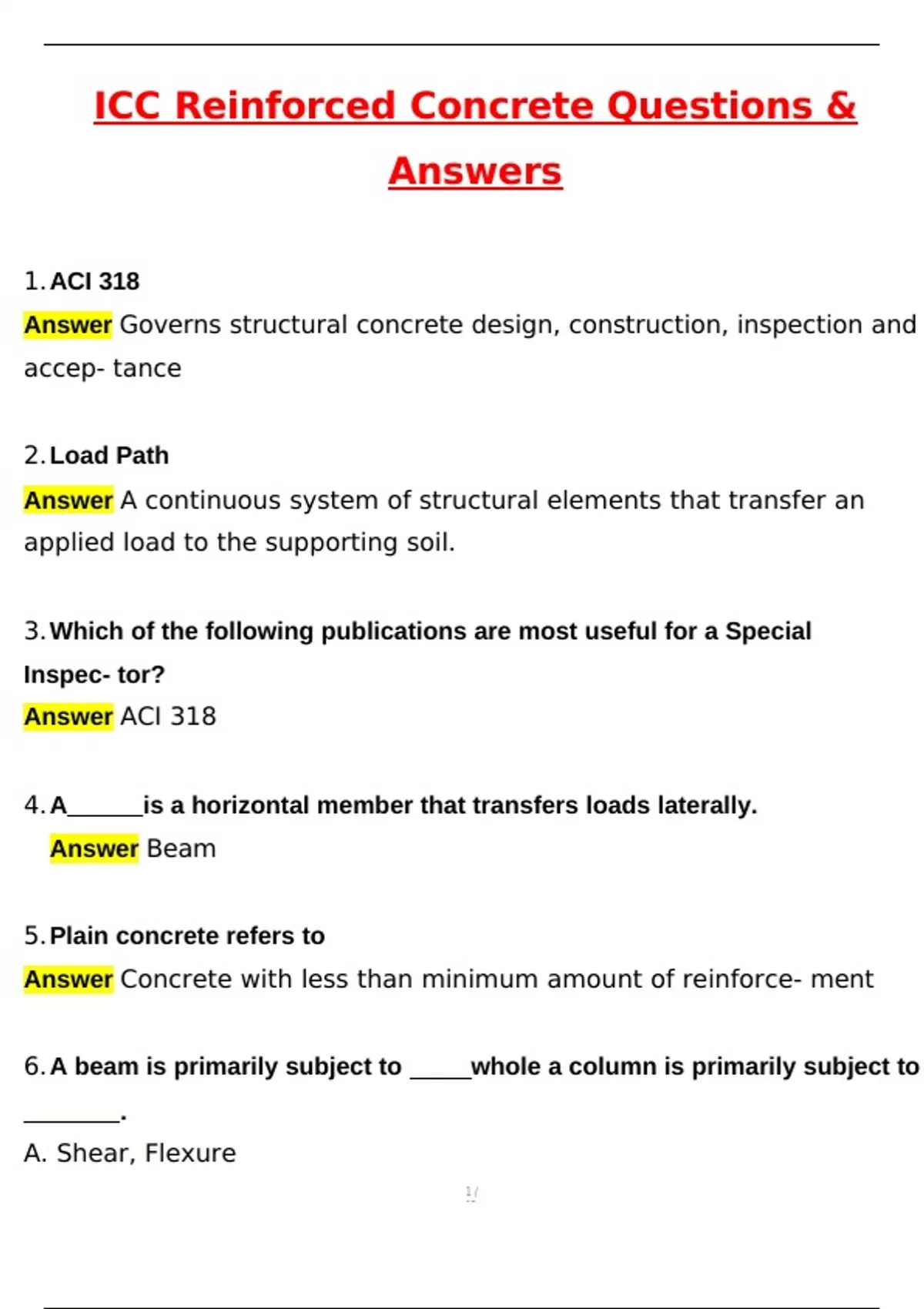

Detailing Of Reinforced Concrete Slabs PDF 1697973490Concrete Slab Cost Per Sq Ft 2026 US Pricing Guide Og Image Pre Tensioning And Post Tensioning A Step Ahead To Producing Flexural In The Form Of Steel Bars ICC Reinforced Concrete 2025 Questions With Complete Solutions Newest 8393509 1200 1700.webp

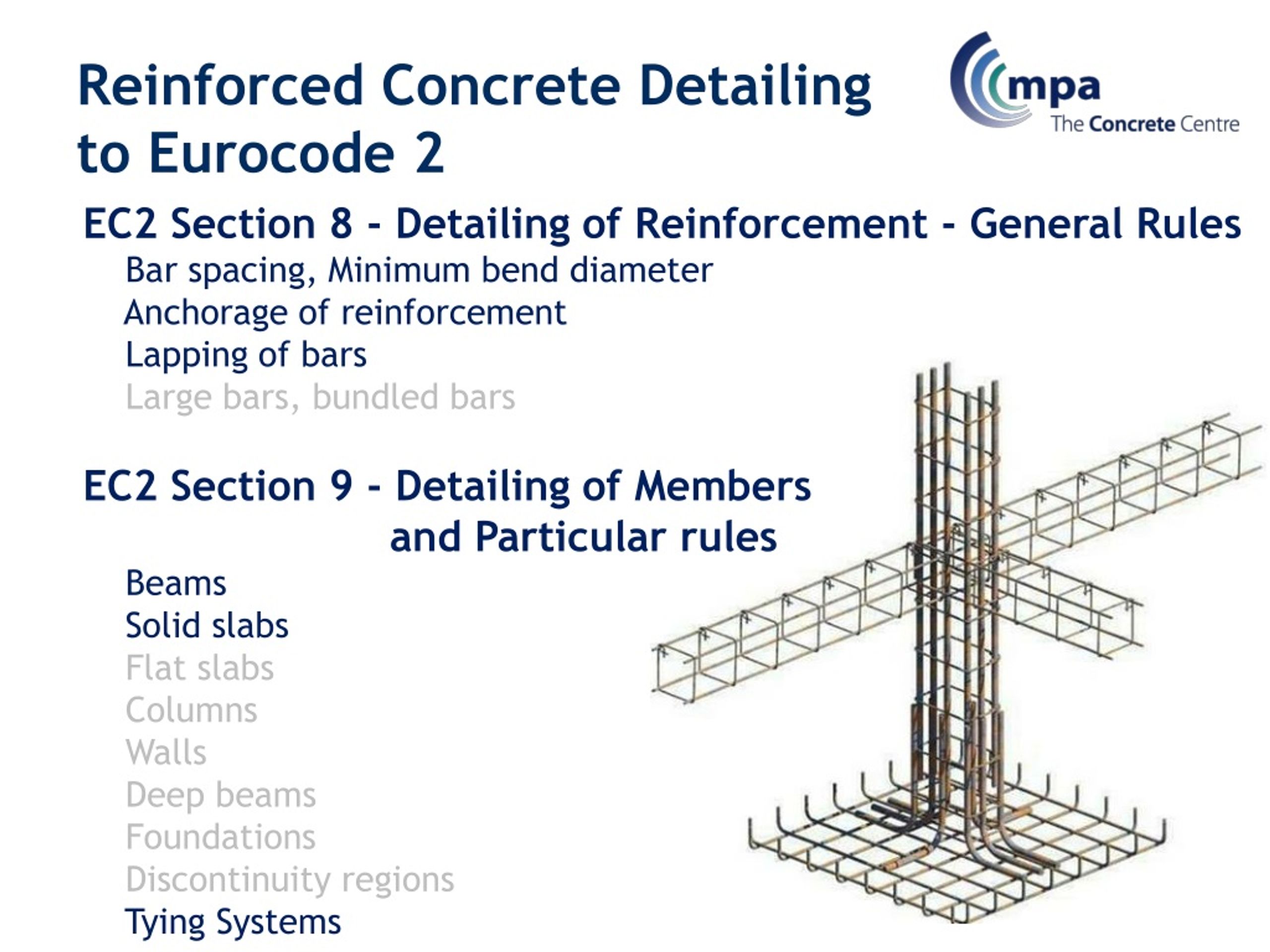

PPT Practical Design To Eurocode 2 PowerPoint Free Reinforced Concrete Detailing To Eurocode 2 L ICC Reinforced Concrete Exam Questions With Correct Verified Answers 8169817 1200 1700.webpReinforced Cement Concrete Work Reinforced Cement Concrete Quality Reinforced Cement Concrete ICC Reinforced Concrete Exam Latest 2025 2026 Update Questions 8047620 1200 1700.webp

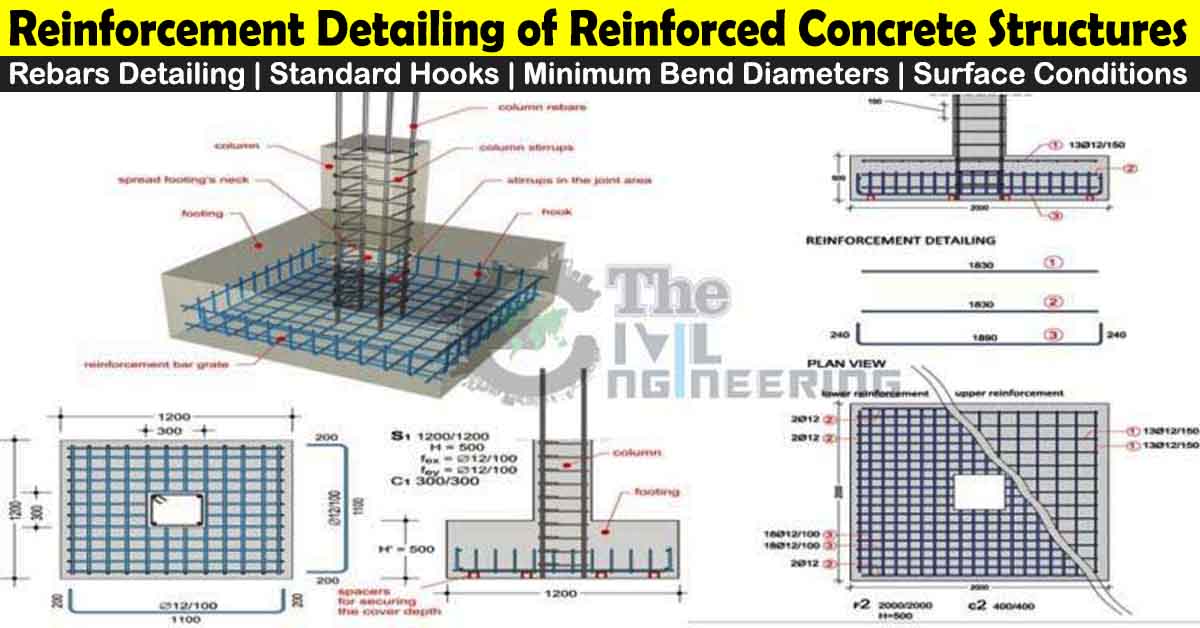

Rate Analysis Of Cement Concrete RCC Detailed Rate Analysis Of RCC Cement Concrete Design Guide For Vibrations Of Reinforced Concrete Floor Systems 136 Cad Drawing Of Plan Of Reinforced Concrete Pavement For Download 136. Cad Drawing Of Plan Of Reinforced Concrete Pavement For Download Detailing Guidelines EC2 PDF Column Concrete 1

Estimating Concrete PDF Beam Structure 11 Concrete PDF Steel Concrete 1CONSTRUCT Launches Revised A Guide To Contractor Detailing Of 5197 In Concrete V15 Concrete Concrete Min W850 H425 Min W850 H425

Concrete A Guide Barrow Concrete Guide ICC Reinforced Concrete Exam Questions With Correct Answers 2025 7861368 1200 1700.webpConcrete Guidelines CreteForm Concrete Concrete Best Practices CONCRETE Chapter 1 PPTX CONCRETE Chapter 1 8 638

For Modern Concrete Structures Amanat 2026 PDF Fibre 1For Concrete How To Reinforce Concrete And Why RPO Reinforced Concrete Hero Opt ICC REINFORCED CONCRETE Final Code Test 60 Questions 2025 Questions 8393501 1200 1700.webpA Guide To Reinforced Concrete BCM A Guide To Reinforced Concrete .webp

Reinforced Concrete Wall Detail 85 Figure4 Reinforcing Concrete Masonary Foundation Edge Reinforced Concrete Slab Guide 2025 2023 Sep 105 Z6 Detailing Handbook Concrete Institute Of Australia Z6 Steel Detailing Handbook 2024 2 Front Cover 1 5 1076x1536 Concrete Driveway In Greenville SC 2026 Guide Concrete Driveway Excavation Greenville

2026 Concrete Masonry Cost Data CD 2026 Concrete Cover Cd Pdp Reinforced Concrete Design Cement Concrete Theories Reinforced Cement Concrete Design Detailing Of Reinforced Concrete Structures Detailing Of Reinforced Concrete Structures